Want to know more about Plastic Upcycling?

Take a few minutes to read our latest perspective published in Nature, in which we highlight the most advanced upcycling methods for converting plastic waste into high-performance materials, fine chemicals or innovative monomers.

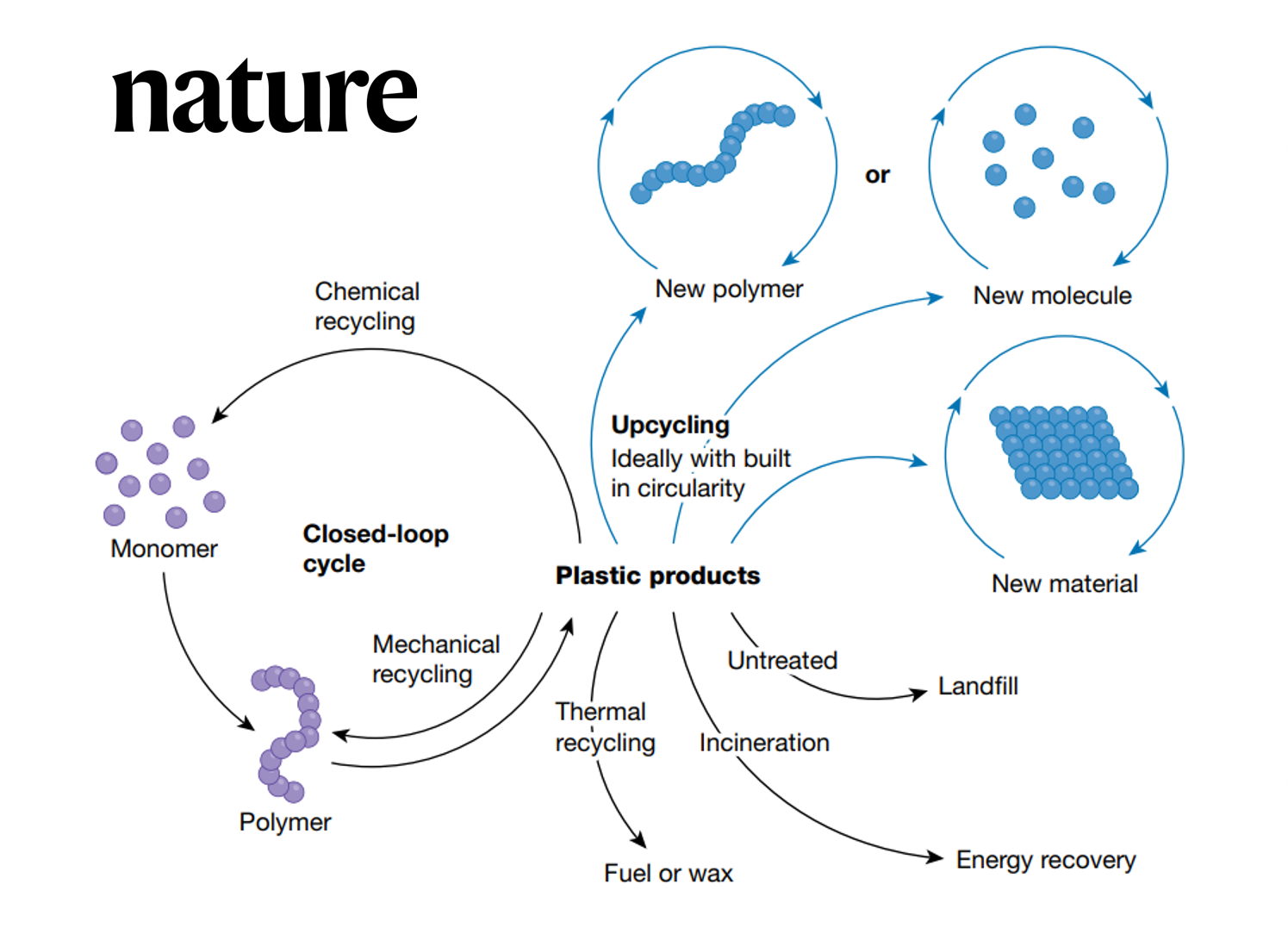

It is well known that commodity plastics do not degrade and permanently pollute the environment. To address

this problem, less than 20% of post-consumer plastic waste is currently recycled in developed countries for energy recovery or reuse as lower value materials through mechanical recycling.

Most discarded plastics are landfilled or incinerated, so plastics that are currently recycled are almost always mechanically recombined, and the limitations of sorting techniques mean that additives, contaminants, mid-sorted polymers or multi-layered products in plastic waste streams lead to substantial deterioration of properties during and after reprocessing. Therefore, mechanical recycling of post-consumer plastics too often results in so-called low-grade or low-utility materials.

For those waste plastics whose mechanical or chemical recycling is prohibitively expensive or unfeasible, the field of chemical upcycling is born, which promises to use chemical or engineering approaches to place waste plastics at the beginning of a new value chain.

The article discusses the different state-of-the-art methods for converting plastic waste into high-performance materials, fine chemicals and value-added specialty polymers. It also highlights the latest innovations in upcycling concepts and methods.

It is mentioned that the overall objective of upcycling is to reuse plastic waste into products with higher “value”. Considering “value” as a broader concept than economic value, given also external, personal and sociological value, encouraging a more holistic approach.

``Polymer-to-polymer upcycling translates into the direct transformation of discarded plastics into a polymer of a different composition that has more economic value than the original material´´

The conclusions identify the need to develop strategies to reduce, reuse and recycle plastic waste, which will be a pressing scientific and societal challenge, not only to reduce the number of discarded plastics polluting the environment, but also to reduce greenhouse gas emissions caused by the manufacture of virgin plastics.

There is certainly a lot of research to be done. Chemical recycling is not yet available at scale and there are many multifaceted challenges that need to be solved to advance a sustainable plastics economy.

At POLYKEY we carry out different PET and BPA-PC chemical recycling processes. If you are interested in knowing more about these technologies, looking for recycling solutions for a specific polymer or exploring possible collaborations, please do not hesitate to contact us.

The article has been written by our CSO Coralie Jehanno, in collaboration with Haritz Sardon, Jill W. Alty, Frank A. Leibfarth, Martijn Roosen, Steven De Meester, Andrew P. Dove and Eugene Y.-X. Chen. A great collaborative work from POLYKEY, POLYMAT, (Donostia, Spain), the University of North Carolina at Chapel Hill (NC, USA), the University of Ghent (Kortrijk, Belgium), the University of Birmingham (Birmingham, UK) and the Colorado State University ( CO, USA).